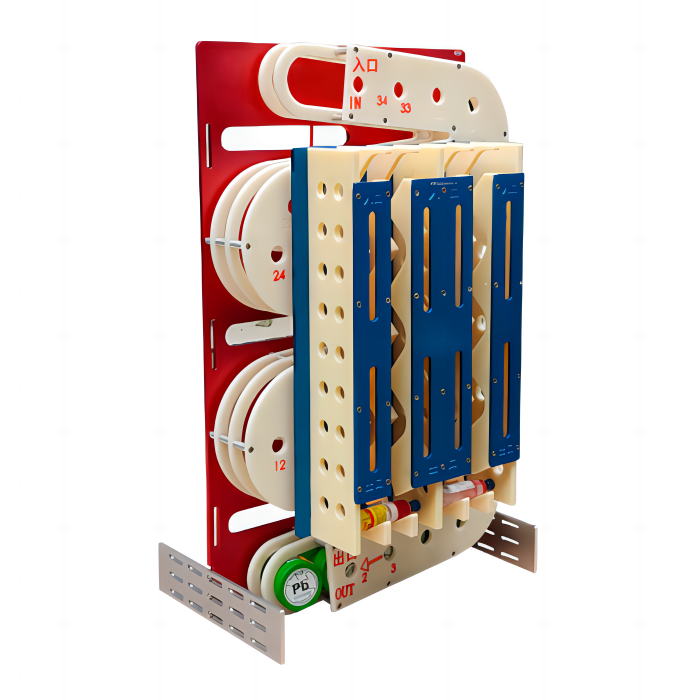

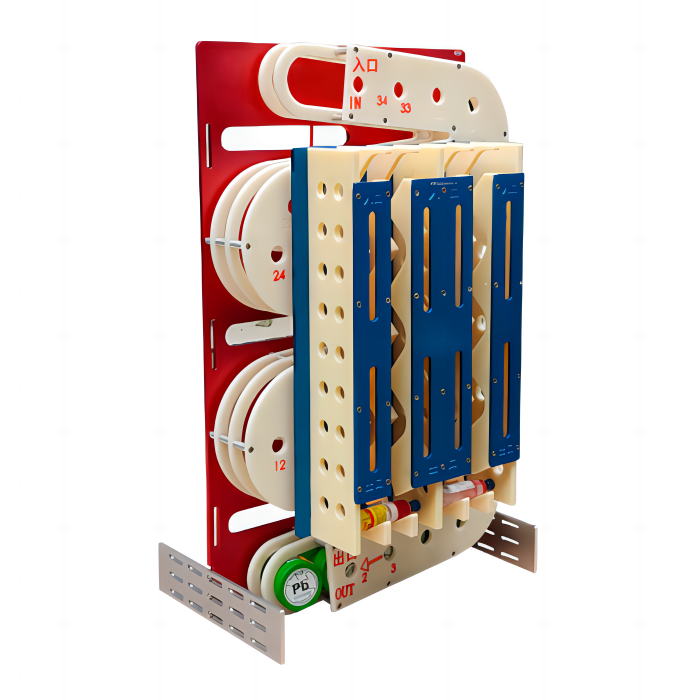

Introduction for Solder Paste FIFO Rack

In the world of electronics manufacturing, precision and efficiency are essential for producing high-quality products. One often overlooked yet critical tool in this process is the Solder Paste FIFO Rack. This article unveils the intricate details and features that come together to create the anatomy of the perfect Solder Paste FIFO Rack. From organization to material selection, we dissect every element that contributes to an optimal soldering experience.

The Foundation: Material and Build

Robust Construction

At the heart of the perfect Solder Paste FIFO Rack is its construction. High-quality materials ensure durability and longevity. Stainless steel is corrosion-resistant and sturdy and is often used in industrial machinery to ensure that the solder paste storage rack can be used for a longer period of time.

Precision Engineering

The design of a Solder Paste FIFO Rack is a marvel of precision engineering. Every compartment, channel, and dispenser is meticulously measured and engineered to facilitate smooth paste flow. This design minimizes friction and paste residue, ensuring consistent dispensing.

Navigating the Compartments

Modular Compartment Design

The anatomy of a perfect Solder Paste FIFO Rack includes a modular compartment layout. This design allows for easy customization based on paste container sizes. Each compartment is tailored to securely hold paste containers, preventing spillage and ensuring stability.

First-In, First-Out Mechanism

Central to the rack’s design is the implementation of the FIFO principle. The positioning of compartments and dispensers ensures that the oldest paste is used first. This rotation prevents paste wastage and guarantees optimal freshness for soldering.

Dispensing with Precision

H1: Controlled storage channels

The storage channels in a Solder Paste FIFO Rack are engineered to provide controlled and uniform paste application. These channels are designed to prevent air entrapment and ensure that the paste flows consistently, leading to precise solder joints.

H1: Avoiding Clogs

Clogging of storage channels can disrupt the soldering process. To prevent this, the perfect Solder Paste FIFO Rack features smooth and wide storage channels. This design minimizes the risk of clogs and ensures uninterrupted paste flow.

Focusing on User Experience

User-Friendly Labeling

User experience is enhanced by clear labeling of compartments and dispensers. The perfect rack includes visible labels that indicate paste type, expiration date, and quantity. This feature streamlines the soldering process and minimizes errors.

Ergonomic Accessibility

The ergonomic aspect of the rack’s design cannot be underestimated. An ideal Solder Paste FIFO Rack places compartments within easy reach, reducing strain on operators and enhancing overall efficiency during soldering tasks.

Conclusion

The anatomy of the perfect Solder Paste FIFO Rack is a testament to the fusion of precision engineering, material science, and user-centered design. From its robust construction to its modular compartments and controlled storage channels, every element plays a crucial role in optimizing the soldering process. As industries continue to evolve, the Solder Paste FIFO Rack stands as a symbol of innovation and excellence.

FAQs

Q: Can a Solder Paste FIFO Rack accommodate different container sizes?

A: Yes, modular compartment design allows for flexibility in accommodating various container sizes. From solder paste container can’s height 72mm to 81mm and diameter 61mm to 67mm.

Q: Is stainless steel the only material option for Solder Paste FIFO Racks?

A: While stainless steel is common, other materials with similar durability and corrosion resistance can also be used. We also have ABS durable material and sturdy acrylic sheet as well.

Q: How does the FIFO mechanism benefit manufacturing efficiency?

A: The FIFO mechanism minimizes paste wastage, ensures freshness, and maintains consistent soldering performance.

Q: Are storage channels prone to wear and tear?

A: Storage channels are designed for durability, and regular maintenance can prolong their lifespan.

Q: Can Solder Paste FIFO Racks be customized for specific manufacturing setups?

A: Yes, the modular design of these racks allows for customization based on individual manufacturing needs.